What Is Toggle Clamp?

A toggle clamp is a fastening device which holds the work piece instantly or Toggle clamps are quick-action hold down clamps used to keep a work piece stationary.

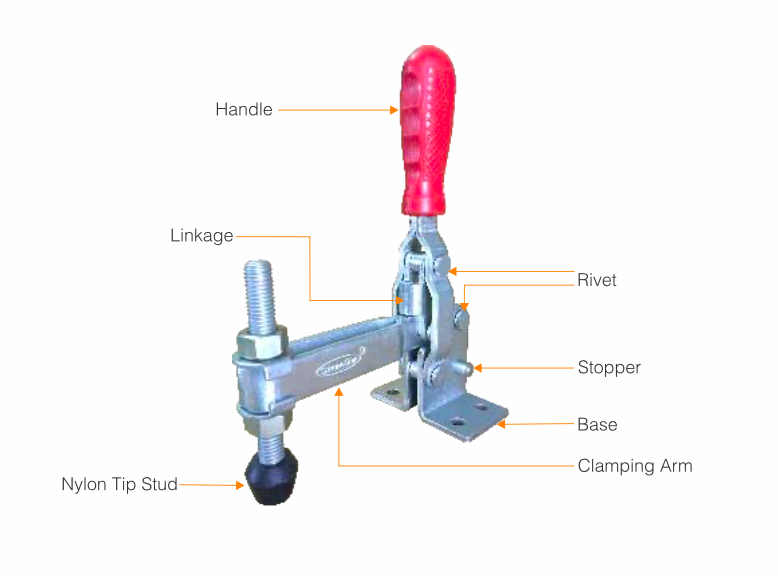

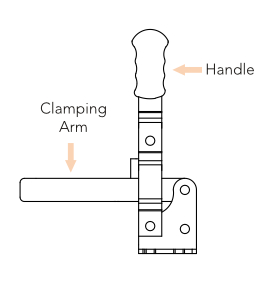

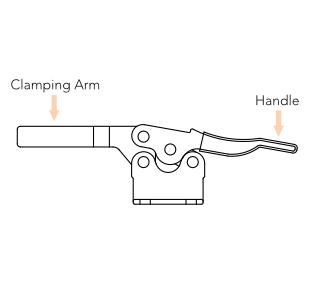

The toggle clamps consist of

- Handle to operate

- Clamping arm to reach the work piece

- Linkages for multiplying the applied force

- Stud for pressure adjustment

- Base for mounting at the workplace

- Rivet

- Stopper

The handle is operated which thereby moves the clamping arm to hold the work piece. A required clamping force is achieved and exerted on the work piece. Under this action the Toggle Clamp Holds the work piece firmly and positively.

Nomenclature of toggle clamps

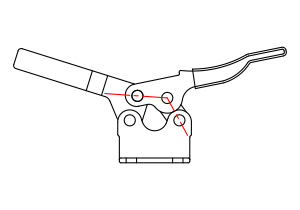

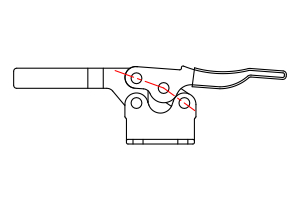

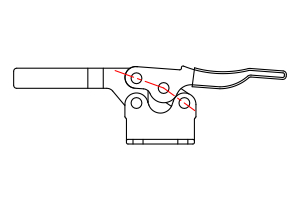

How toggle action works

Toggle action clamps operate through a linkage system of levers and pivots. The fixed-length levers, connected by pivot pins, supply the action and clamping force. Toggle action has an over-centre lock point which is a fixed stop and linkage. Once in the over-centre position, the damp cannot move or unlock unless the linkage is moved. All types of toggle clamps have this same action, just oriented differently.

Unclamped Position

Center Position

Over Center Position

Clamped Position

Holding capacity

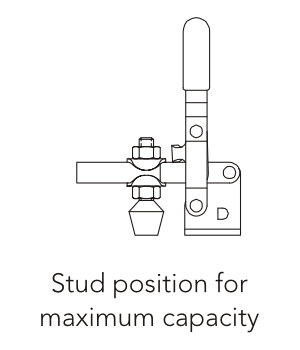

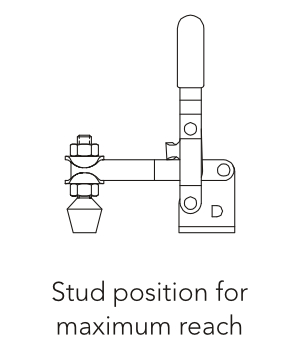

The “holding capacity” listed for each toggle clamp refers to the maximum external force that clamp can safely resist in its locked position without incurring any permanent deformation. For hold-down clamps, holding capacity is measured with the stud as close as possible to the handle, and will be less at the end of the clamping arm.

Clamping force

Clamping force, the amount of force actually applied to the workpiece by closing and locking the clamp, is generally less than the stated holding capacity. This allows the clamp to have ample capacity to resist external machining forces. Actual clamping force depends on many factors including stud position, proper stud-height adjustment stud cushioning workpiece material, and the clamp’s mechanical advantage

Types of toggle action

The types of Toggle Clamp depends on one of the action given below:

Vertical Hold Down Action

Clamping arm and operating handle move in the same direction.The operating handle is vertical in clamped position

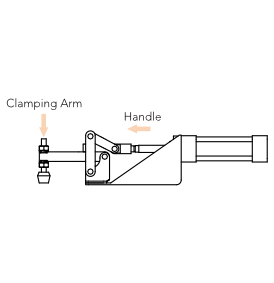

Horizontal Hold Down Action

Clamping arm and handle bar move in opposite direction. The Operating handle is horizontal in clamped position

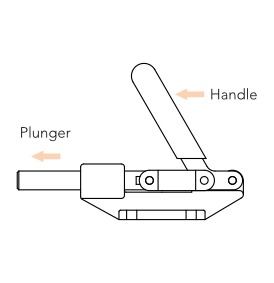

Horizontal Straight Line / Push-Pull Action

The handle is easy to operate and moves the plunger of the clamp in and out along its axis.

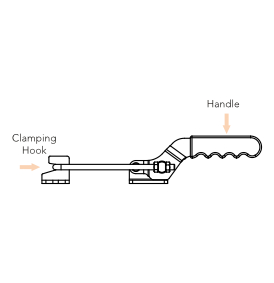

Pull / Latch Type Action

The handle has to be moved to engage the clamping arm ( hook) around the latch. Further, the handle is pulled back to attain the lock position. Ideal for sealing chamber doors or mold closures

Pneumatic Toggle Action

These clamps combine advantages of the clamping by toggle actions and pneumatics. Pneumatic clamps are also available in swing and leverage actions.

Benefits Of Pneumatic Clamps:

- Increase Productivity

- Can Operate several clamps at one time

- Reduces operator fatigue

- Can operate clamps sequentially

- Can operate clamps remotely for hard to reach areas

- Improves safety and ergonomics

- Consistent and controllable clamping forces

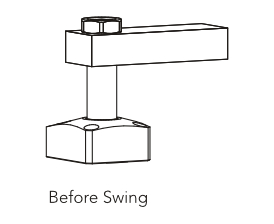

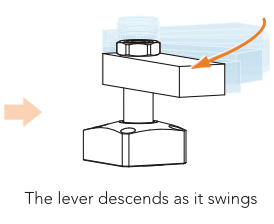

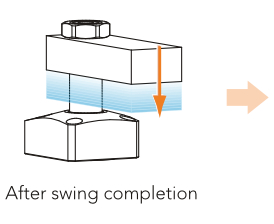

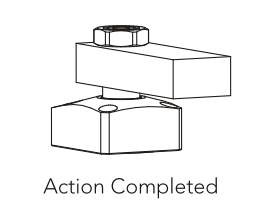

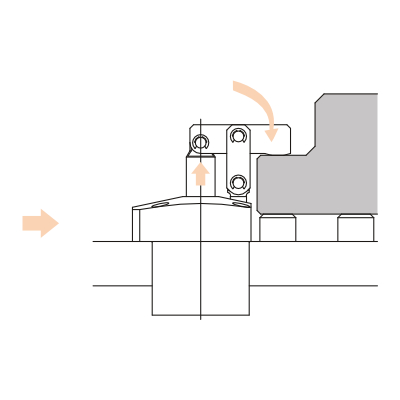

Swing Action

Swing action provide quick swing-and-clamp movement, where the clamping arm first pivots 90 degrees before drawing down on the workpiece. The clamping arm pivots up and out of the way within its mounting footprint. Swing actions are used to increase productivity while working in tight spaces. Swing action are available in pneumatic and hydraulic.

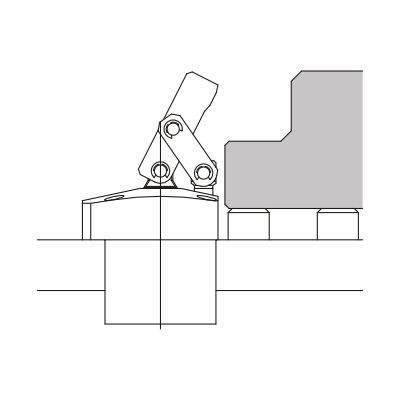

Link / Leverage Action

Clamping arm arcs up and out of the way to accommodate hard-to-reach or hard-to-hit clamping points. Link clamps uses the beam mechanism.

Hydraulic Clamps

Hydraulic clamp uses hydraulic systems to position, support and clamp parts for various purposes. Hydraulic clamps provide a consistent, repeatable force in a relatively small wight and size envelope, the work piece can be secured, in less time, with more accuracy and repeatability without sacrificing valuable fixture space.

Benefits of Hydraulic Clamps:

There are many benefits associated with hydraulic clamps, some of which include:

- Reduced setup time

- Clamping consistency

- Improved part quality

- Improved productivity

Types of Hydraulic Clamps

- Swing Action

- Link / Leverage Action

- Threaded Body Cylinders

Heavy Duty / Automative Weldable Clamps

Heavy Duty / Automative Weldable Clamps are designed to be adaptable & durable for heavy duty applications. They serve requirements of high clamping forces & long service life, Its unique design offers flexibility in clamping force. These clamps are designed to push the upper limits of performance with very high holding capacities and withstand harsh manufacturing environments. The clamping arm & handle can be welded are the desired angle to suit the individual requirements of work pieces. Hardened steel pivot, pins, bush, high strength forged clamping arms and hardened plungers provide long life.

Necessity of Toggle Clamp

Men,Machine, Method and Material are the most important factors in any production progress. Particularly clamping of job ensures repeatability, consistency, quality and also safety at mass production level

Advantages of Toggle Clamp

- To achieve accuracy, consistency in production process

- To make production process operator friendly.

- To avoid operators fatigue

- To increase productivity

- To avoid occurrence of accidents

Selection of Proper Clamp

This catalogue helps you to select correct clamp for your job. For most of the ordinary applications, consideration of the following points will lead to proper selection of clamp.

- Size & Shape of the parts to be held

- Uniformity of part size

- Holding capacity required in kgs

- Strength & dexterity of the operator

-

Operators suitability / ergonomics

-

Frequency & cycle time of the operation

-

Environmental factors like heat, moisture etc

-

In case of pneumatic clamps its cycle time and sequence